Design & Engineering services

We expertise in the high end engineering competency of pilot prototype development.

We cover for all aspects of the complex multi disciplinary machine desgin & engineering.

Design & Engineering services

We expertise in the high end engineering competency of pilot prototype development.

We cover for all aspects of the complex multi disciplinary machine desgin & engineering.

Overview

D&D is one of the most extreme challenge in mechanical engineering. We started off from the drawing board and over years have perfected the knowhow to deliver customized pilot products.

The D & E activities are managed with streamlined project planning over sequence of predetermined milestones. The process is detailed herein.

The Background

The product D&D deals with range of engineering branches and expertise in numerous sophisticated tools. This process demands high end skills in machine design and expertise across a vast spectrum of engineering fields and each branch and expertise are a specialization. The adroitness in Integrating expertise in entire gamut of engineering branches is kernel to proficiency in the forte of machine design.

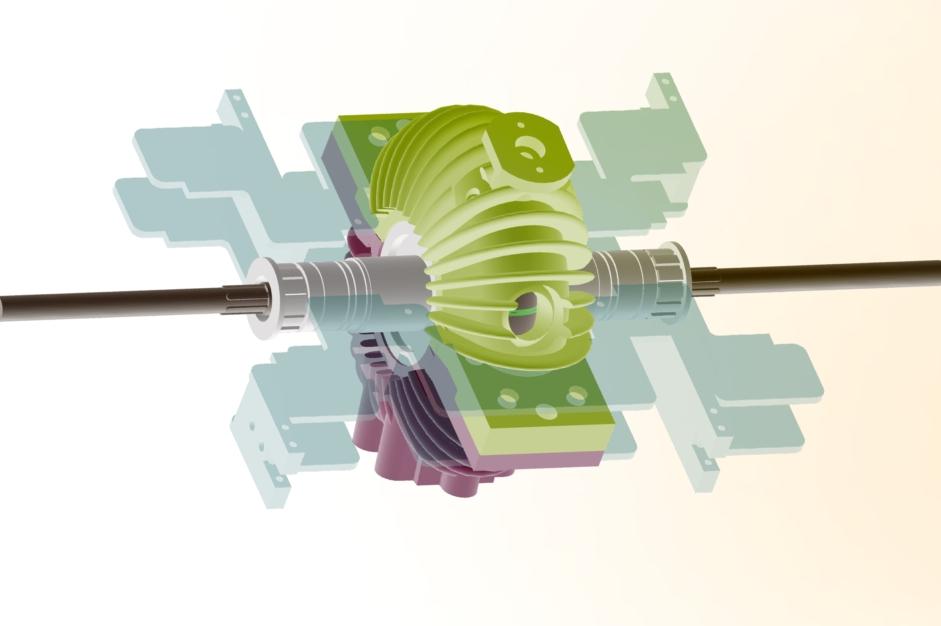

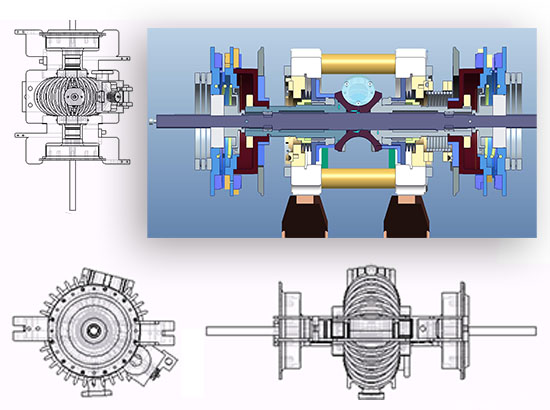

GYATK initiated the D&D process by conceiving preliminary concept prototype assembly made of various components and formulated its mathematical, Digital and Physical Models. These were refined over various Iterative correction cycles. Various Design techniques were used for Failure Mode Analysis and identifying weak-points, limitations, and Possibilities.

The RVCR specific design process techniques, methods and activity flow layout structure developed by GYATK and it comprises.

Design planning & Virtual engineering

Process Planning

Process Planning

Each project is planned, and its detailed activity fine print mapped out to. The objectives, milestones, main heads, subheads, and their interdependencies are laid out using

- MVP Analysis and determination

- Project activity Plan and scheduling

- Resource planning

- Costing and Budget

Math & Virtual Modelling

- Design requirement analysis

- Specification evaluation & Finalization

- Systems Accessory Specification Synthesis

- Readying of individual data sheets of subsystems

- System modelling scheme verification

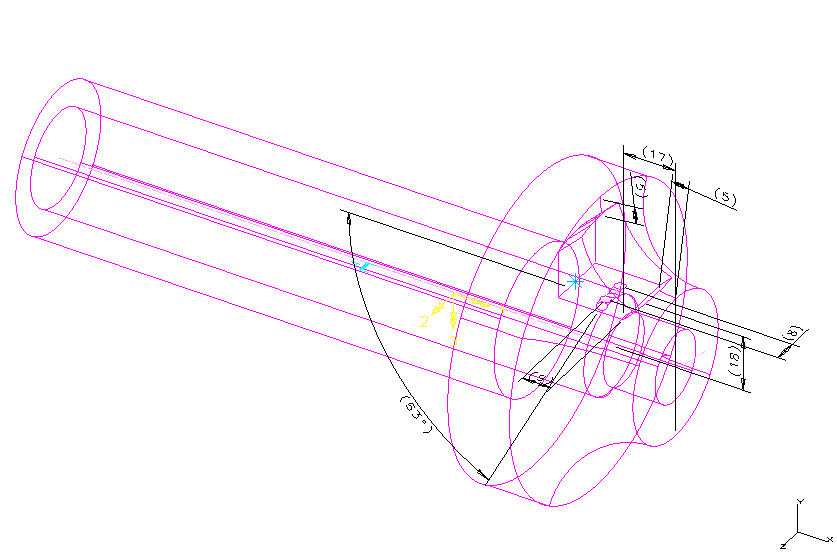

- Geometry formulation & Preliminary DFMA (Design Failure Mode Analysis)

- Function animation and drafting scheme confirmation

- Parameterized model and assembly creation

- Mechanism Modelling

- Component Modelling

- Sub-assembly & Assembly Modelling

- Data exchange with up and downstream process

- Manufacturing Process Development

- Material Selection

- Metallurgy and Metallurgical Process

- Product manufacturing scheme, machining Plan package

- Product Mass manufacture analysis and Optimization, (Pre-Manufacture and Manufacturing Pilot Requirements)

- Precession machining and finishing

- QC Metrology & inspection Scheme formulation

- Assembly and assembly line scheme formulation and optimization.

- Other custom needs

- Cooling

- Tribiology

- Ergonomics, Coatings, stowage, Handling, Tools, Equipment’s Control and Management Systems.

- Ignition, Fuel Safety, Security systems.

- Closure Constraints &Tolerance Optimization.

- QC Metrology & inspection Scheme formulation

- Upward Systems Integration Scheme Formulation and Analysis.

- Upward System Specification Finalization.

- Upward System Testing, Recording, Tuning, calibration, Analysis, Suiting.

- Data acquisition, Logging, Processing and Analysis Machinery; Tooling; Testing, Manufacturing cost optimization.

- Mating; Assembly Procedures Standardization.

- Mechanized assembly Analysis.

- Standardization / homologation

Analysis, Simulation & Design Freeze

- Model Preparation for Analysis

- MBD: (Multi Body Dynamics) kinematics evaluation and correction

- CFD: (Computational fluid Dynamics)

- FEA: Finite Element Analysis. Structural and thermal analysis

- Steady thermal State Model Development and Combustion analysis.

- Design freeze; GD&T and Drafting

- Deducing Component Level Tolerances from Subassembly Level Functional Tolerances.

- Tolerance stack-up analysis and Optimization.

- Tolerance Attainability; Sustainability; and Viability Analysis.

- Tolerance Allocation coordination with Drafting and Quality Control.

- Drafting of Components for Manufacture

Physical Engineering

Prototyping / Pilot Product development

- Component manufacture and Assembly

- Inspection and QC

- Mating and assembly

- Sub assembly Calibration and Functional Integrity check

- Assembly realization

- Acc Systems integration

- Assembly creation

- Testing and Trials

- Test bed performance

- Design accuracy confirmation

- Validation and certification

- Product suiting

- installation suiting

- Product tuning

- Performance validation

Commercial aspects

Commercial aspects

- Standardized Stowaging Handling Consumables and Time motion optimization.

- Installation, Logistics, Warranties.

- IT Support

- Performance Validation

- Regulatory Compliances

- Product Certification

- Grounding Sense check

- Statutory Publications.

Summary

The RVCR concept is an invention in the field of kinematic mechanism that seeds a new breed of highly energy efficient machines with possibilities of newer functionalities to effectively deal with 21st century market drivers.